Moisture happens! Your filament can get wet and give you lot`s of headaches. Starting with surfaces with pocks and holes, stringing, bad bed adhesion, layersplitting and clogs in your hotend.

Some people never experience problems with wet filament. If you live in an area with low humidity and only print PLA or you never have old spools (because you print a lot), maybe you are one of them. But most of us can have issues. If you can easily break your PLA/PETG/ABS/ASA, it is truly wet.

Storing Filament

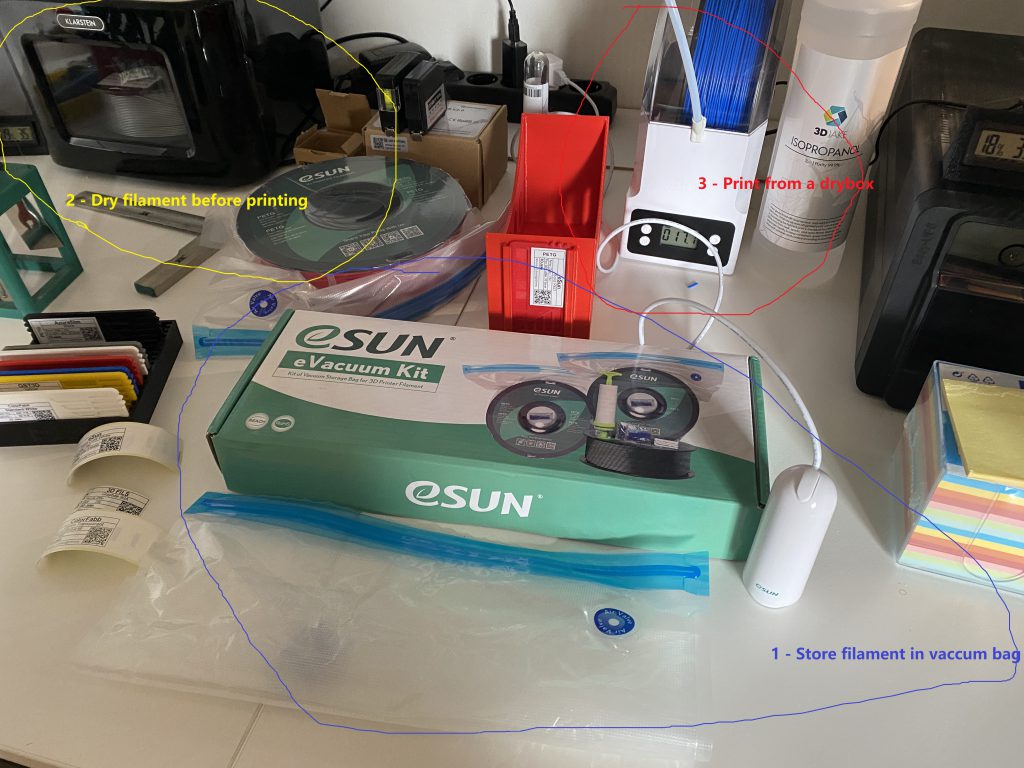

To prevent moisture, everything starts with storing your filament dry. Two ways of doing that:

- vacuum bags with silica desiccant gel

- Drybox (for more spools) which have a layer of silica desiccant on the bottem and can be closed airtight

Drying filament

Drying your filament is the easiest in a food dehydrator or filament drybox. Unfortunally a lot of filament dryboxes are not the best for getting all moisture out of your filament. While they do a good job for PLA, for other filaments (where higher temperatures are needed), they aren`t really an optimum choice. With dryboxes with an external fan, you can have great results. EIBOS has a good one (from what i`ve heard). A good food dehydrator makes all filaments dry really great.

Even eSun puts on their website that TPU needs to be dried 4-6hrs @ 55c before you start printing.

eSun eBox Filament drybox and Klarstein food dehydrator (tuttifrutti machine)

New filament out-of-the-box can have moisture! So even new filament needs to be dried first.

Filament drying times

| PLA | 4-6 hrs | 45c |

| TPU | 4-6 hrs | 55c |

| PETG | 4-6 hrs | 65c |

| ABS/ASA | 4-6 hrs | 75c |

Keep filament dry while printing

Specially on long prints, your filament can get absorb moisture while printing. Specially for TPU and Nylon, filament can get wet in a couple of hours! Printing from a filament drybox prevents getting moisture in your filament while printing.

Conclusion:

- Store your filament dry with sealed vacuum bags (or drybox)

- Dry your filament with a food dehydrator (or good filament drybox)

- Print from a filament drybox